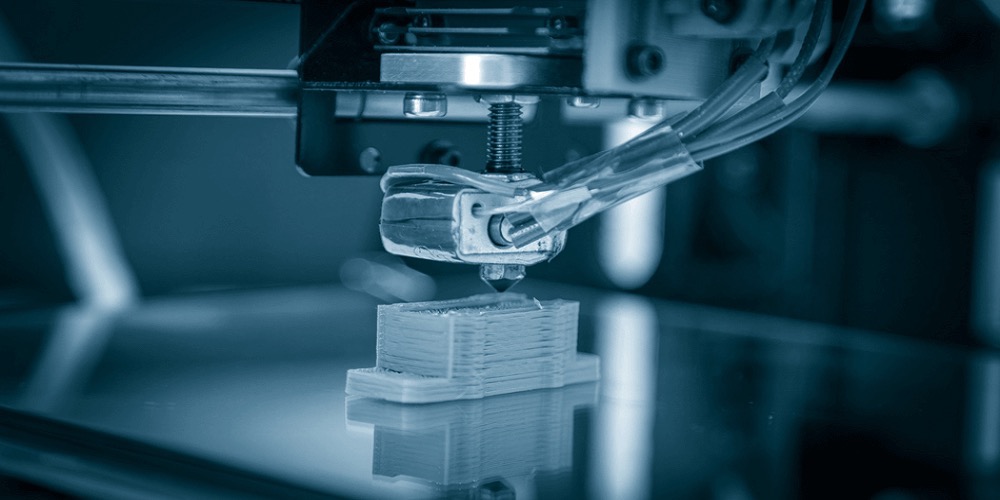

The 3D printing manufacturing process has been around for a long time, but it has only recently gained popularity in the manufacturing industry. Also knows as additive manufacturing, 3D printing offers a lot of advantages to manufacturers. But, just as every other manufacturing process, 3D printing also has its drawbacks.

3D printing has been a revolutionary invention where a computer file turns into a tangible prototype and then a useable product. More and more industries are moving towards 3D printing as their primary manufacturing process, and for good reasons. However, they still need to deal with the disadvantages of 3D printing too.

This article enlists the advantages and disadvantages of 3D printing in a precise and comprehensive manner. The purpose of this article is to help readers with the selection process so they can decide which manufacturing process they should employ. One thing is quite clear, 3d printing is one of the better options if you want to help the environment.

Advantages Of 3D Printing:

The additive manufacturing process offers multiple advantages over the traditional subtractive or injective manufacturing process. The most notable advantages are in terms of design, speed, and waste management. Let’s take a closer look at more benefits of 3D printing.

1. Reduced Waste

When you compare 3D printing to other manufacturing processes like CNC, you can see how much raw material is saved by manufacturing with 3D printers. While using a subtractive process, raw material is further cut, carved, and shredded to make smaller pieces. On the other hand, while 3D printing, raw material is morphed into the exact shape with very low wastage. This helps the environment as well as reduces the cost of raw materials.

2. Speed

3D printing is much faster than any other manufacturing process because making prototypes with 3D printers takes very little time. Once the design is final, you can have a prototype in your hands within a few minutes. The faster the prototype is given the green light, the quicker the whole process starts and finishes.

3. Overall Cost

3D printing has a much lower overall cost because the whole manufacturing happens inside a single automatic machine. It saves a lot of time and labor costs, and of course, we mentioned the reduction in cost due to limited raw material usage. So, if you are looking to save time and money, 3D printing is your best bet.

Disadvantages Of 3D Printing:

3D printing is the next big thing in the manufacturing industry, but it has its cons too. To make a better and well-informed decision, you have to know about the pros and cons of 3D printing. We already saw the pros, now let’s take a look at the cons.

1. Material Compatibility

The biggest disadvantage of 3D printing is that it only works with plastic and a few metals. Because 3D printing involves the use of high temperatures and not all metals respond well to high temperatures, it limits the options of the manufacturer.

2. Size Restriction

Another significant limitation of 3D printing is that 3D printers have small printing chambers, which limits the size of the part that you can make. If you need bigger parts, you will have to use multiple printers to make the various components of the part and then join them together, which increases the cost, reduces the speed, and defeats the whole purpose of using 3D printing.

3. Copy Cats

3D printers are getting cheaper every day, so there is a chance that someone will steal your design, manufacture the same product, and sell it under their own banner. Because material options are so limited, there won’t be a big difference between the quality too.

There are various advantages and disadvantages of 3D printing, but if done right, the advantages outweigh the disadvantages of 3D printing. So, if you can find the right manufacturer, 3D printing is a great manufacturing process.